01. About →

What are we talking about and why is it important.

Suction stabilizers help reciprocating pumps balance operations in two ways: by offering the suction manifold a readily available reservoir of pumped fluids and providing both the reciprocating pump and charge pump with a mitigation element to isolate the two pumps from each other.

In what is known as cavitation, reciprocating pump cylinders start to take in vapor creating a void when the suction manifold has a hard time refilling with fluid. During the cavitation process, the cylinders will produce a great deal of negative energy transferred into the pumped liquids.

However, installing a suction stabilizer at the suction manifold port, the manifold gets additional media, thus eliminating situations in which it would lack fluid, resulting in essentially taking away cavitation.

Aside from virtually eliminating cavitation, suction stabilizers can also remove negative energies in the fluids produced via the water hammer effect caused by pump valves rapidly opening and closing. Compressible elements are designed to absorb energies present in the pumped liquid. This, in turn, leads to pump isolation, such as when reciprocating pumps are isolated from charge pumps and vice versa. The negative impact created by the reciprocating pump then never makes it back to the charge pump, extending the life of the pump expendables by taking away pump chatter.

By letting you operate pumps evenly and consistently, suction stabilizers can prevent most problems associated with pressure surges or pulsations, even in the most challenging piping conditions experienced. This not only lets you avoid excessive downtime but also helps you cut back on inconvenience and costs associated with system repairs and replacements.

Think of it as an investment in your investment. A means to make sure your pumps are operating as they should. To make the most of your investment into suction stabilizers, however, it’s critical to ensure that you are making the best choice. Fortunately, there are numerous options available to you. Unfortunately, they are not all made equal.

To figure out the best suction stabilizer for you, it’s essential to understand what each choice has to offer. Today, most suction stabilizers in the market are designed to prioritize efficiency, reduce harmful surges and pulsations, and eliminate wear to ensure smoother operations. However, they also have their limitations, which can keep you from getting the results you’re looking for.

Suction stabilizer options available to you include:

There is a significant misconception regarding standpipes. A standpipe is not a suction stabilizer, but for many years, the primary choice for creating a favorable position for mud pumps was standpipes installed off suction manifolds. This solution was based on the idea of having a gas over fluid column available at the reciprocating pump’s suction manifold in an attempt to avoid cavitation.

However, as standpipes are typically installed on the “deadhead” side of suction manifolds, they can’t get fluid into cylinders to avoid cavitation. Not to mention that they don’t result in any isolation between reciprocating pumps and charge pumps. The gas over fluid column shows its limitations because of inadequate maintenance or a lack of replenishing the standpipe’s gas charge.

Invented to address the pitfalls standpipes have, cartridge vessels made it possible for gas to be contained by separating gases from drilling fluids with a rubber membrane. Unfortunately, your problem with cartridge vessels is they will eventually fail. When they do, compressibility is lost, rendering the suction stabilizer incapable of absorbing any energy and leaving the vessel utterly ineffective. Every time a cartridge vessel fails, it leaves the reciprocating pump less efficient, which ultimately costs time, money, and human resources, commodities that are precious on a drilling rig.

Even though the cartridge vessel is an improvement above the standpipe, the misinformation or assumptions that people make regarding the stabilizers still render it pretty ineffective. One common mistake is installing a stabilizer in place of a standpipe, resulting in an improper location. A stabilizer’s intended design and purpose are installed directly off the suction manifold between the reciprocating pump and the charge pump.

Filling with the proper type of gas and keeping the vessel properly charged are also problems. Still, even when cartridge vessels are appropriately charged with nitrogen, the best they can do is only use compression to absorb energy.

Cartridge vessels effectively isolate pumps, but cartridge failure and proper gas charging remain as concerns.

After standpipes and cartridge vessels, maintenance-free suction stabilizers appear to be a decent choice, not requiring regular service and generally considered more efficient. Unfortunately, they aren’t free from their drawbacks.

Maintenance-free units work by utilizing massive cellularized rubber tubes. Pumped drilling fluid fills the middle of the tube and compresses against the outer and inner walls. Due to the required surface area and compressible element volume, maintenance-free stabilizers are extremely large and cumbersome for a standard pump skid.

Additionally, as cellularized tubes are only made to reduce energies coming from the reciprocating pump via compression, they cannot reduce energy by any other method. This limits their ability to mitigate energy, thus requiring these vessels to have massive tubes installed.

More convenient and more efficient, maintenance-free suction stabilizers addressed what standpipes and cartridge vessels couldn’t.

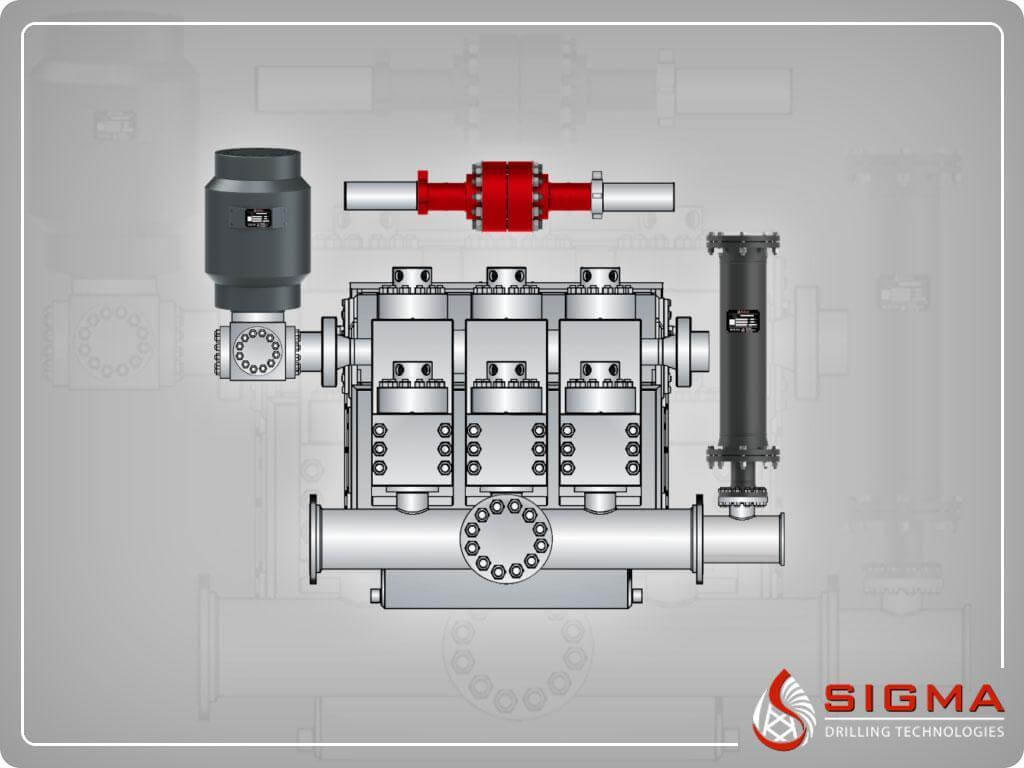

As the most advanced and versatile suction stabilizer on the market, the Charge Free Stabilizer™ (CFS) offers energy reduction without any gas charging and ensures premature failure is not a problem. It features a patent-pending design utilizing multi-phase energy mitigation, making room for both kinetic exchange and compression without the need for unreliable cartridges or massive cellularized tubes.

A complement to Sigma Drilling Technologies’ Charge Free Conversion Kit® (CFC Kit), it takes advantage of the kit’s revolutionary pulsation control process, superseding all stabilizer options available in the market today with these benefits:

Charge Free Stabilizer™: advanced technology creating a better solution

Drilling technologies have come a long way, and you can take advantage of improvements at every step by choosing a suction stabilizer that takes on issues that other options cannot. A culmination of solutions, that choice will show you, there’s always an answer to a problem when the right experts are working together to achieve standout results. To learn more about suction stabilizers, don’t hesitate to contact our team of pulsation experts today!